Download Free Software Lectra Romans Cad Free

Apr 9, 2018 - FileFixation.com is a new file sharing web service which gives you access to literally hundreds of thousands of direct downloads including.

Computer-aided design Assignment • model (raster, vector, 2D, 3D, render, animate, simulate.) a possible final project, and post it on your class page As a homework assignment this week, I modeled what I needed for the final project. They are surfboards, waterproof containers, fins (optional). I am planning to mill the surfboard to the 8th week (make something big) and intend to print the containers 3D in the 5th week. Also, I designed 2D for the final project's original logo.

Surfboard design with 3D software software I chose a CAD software specialized for surfboard design. I used from that software based on. There are other softwears and interfaces were pretty much the same. AKU Shaper Free Two Week Trial monthly subscription($45 / month) available Shape3D Free(lite) costs 435 € a year to export STL files BoardCAD open source trouble with exporting STL files modelling I do not have any knowledge about surfboard design, and I do not want my original design to ruin the final project, so I decided to copy my existing surfboard design First, I measured my board dimensions. The length of the board was 2440 mm(96 inches), the maximum thickness of was 750 mm(29.5 inches), and the maximum width was 560 mm(22 inches).

I started the application and opened and chose the blank board, which is appropriate for the size I'm going to design. I can modify the surfboard profile freely by moving blue bezier points. I added blue bezier points on the board profile at every 100 mm from the nose of the board. I adjusted blue bezier points to match my surfboard. Then, I adjusted the rocker profile, too. I exported my design in STL format and opened in 3D printing slicer software(Simplify 3D).

It looked like my surfboard. The model file AKU Shaper format is STL format is After modelling I didn't realize there are CAD tools specialized in designing a surfboard. There was to design a surfboard with Fusion 360, but It doesn't look easy enough. Now that I understand the reason there are specific industry-oriented CAD softwares.

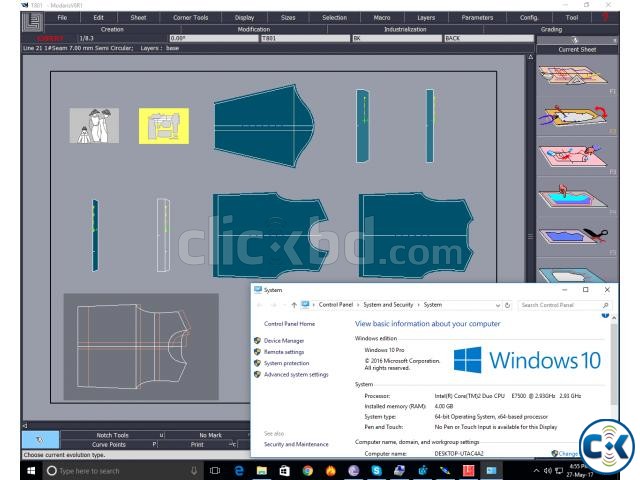

I wondered if there were any CAD for a particular purpose? I did some my homework. Fasion(pattern making) Optitex‘s ODev, OPro and OSel programs; Kaledo from Lectra; Telestia Creator; FashionCAD and etc. Footware Romans CAD; Shoemaster CAD; ICad3D+; ElitronCAD 2D Footwear; great list is Architecture AutoCAD Architecture; Chief Architect; TurboCAD; BricsCAD; ProgeCAD and etc. Watertight enclosure design As a design of a watertight enclosure, I assume a box like an image shown below. There is a groove in the top of the box wall, and rubber-made O-ring is placed in it.

There is a convex part on the back side of the lid. When the lid is placed on the box and pressure is applied, the O-ring will be crushed, and the waterproof will be achieved Credit: Tinkerer software I used AutoDesk Fusion 360 for my box modelling. Modelling First, I drew a rectangle sketch on XY plane and extruded the profile plane. Then 'Modify/Shell' the box and place a lid as a 'New Body' on the top of the box. Select the top of the box as the profile plane and 'Create/Sketch' a groove profile on it. Basic biomechanics susan hall 5th edition pdf. 'Extrude' it from the back side of the lid with the operation 'Join.' Then Modify/Combine' with the box as 'Target Body' the lid as 'Tool Body' and 'Keep Tools' The operation made a groove on the top of the box.

'Modify/Fillets' at all corners. In this design, the wall thickness of the box became thick enough to be dug a groove, it takes time and material cost in 3D printing.