Difference Between Squirrel Cage And Wound Rotor Induction Motor Pdf

Difference Between Slip Ring & Squirrel Cage Induction Motor Difference Between Slip Ring & Squirrel Cage Induction Motor The squirrel cage induction motor is the most popular type of AC motor. It is very commonly used in industries because it is very cheap, robust, efficient, and reliable. The slip ring motor has very little application in industries. Rarely 5% – 10% slip ring motors are used in industries because it has several disadvantages like it required frequent maintenance, having a high copper loss, etc.

One of the major difference between the slip ring and the squirrel cage motor is that the slip ring motor has an external resistance circuit for controlling the speed of the motor. Whereas in squirrel cage motor, it is not possible to add any external circuit because the bar of the motor is permanently slotted at the end of the ring. Some other differences between them are explained below in the comparison chart. Comparison Chart: Slip Ring V/s Squirrel Cage Motor • • • Comparison Chart Basis For Comparison Slip Ring Motor Squirrel Cage motor Defintion The rotor of the motor is constructed as a slip ring type. The rotor of the motor is a squirrel cage type. Rotor Cylindrical laminated core with parallel slots and each slot consist one bar.

Synchronous motor; Induction motor: Stator winding is similar to that of a synchronous motor. It is wound for a specific number of poles. A squirrel cage rotor or a wound rotor can be used. In squirrel cage rotor, the rotor bars are permanently short-circuited with end rings.

The slots of the rotor are not parallel, but are skewed. Other name Phase wound rotor Cage motor Construction Complicated Simple Resistance Added external to the rotor The rotor bar is permanently shorted at the end of the ring, thus it is not possible to add any external resistance. Starter The rotor resistance starter can be used. Rotor resistance starter can not be used. Chertezh autocad dvuhetazhnij dom s mebeljyu. Starting Torque High Low Brushes Present Absent Maintenance Frequent maintenance required Less maintenance required Copper Loss High Low Efficieny Low High Speed Control Possible Not Possible Power Factor Low HIgh Cost Costly Cheap Starting Current Low High Uses Use in hoist, cranes, elevator where high torque is required. Use in lathe machines, fan, blower, profiting machines, etc.

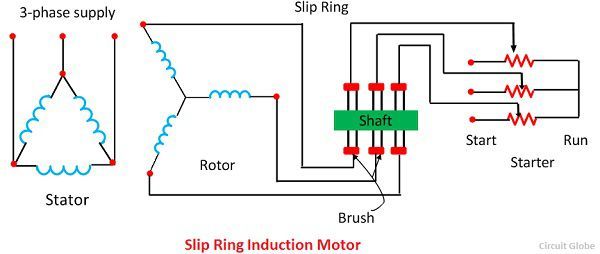

Definition of Slip Ring Motor The motor which employing the wound rotor is known as a slip ring induction motor or phase wound motor. It consists laminated cylindrical core which has a semi-closed slot at the outer periphery and carries three-phase insulated winding. The rotor is wound for the same number of poles as that of the stator. The three finish terminals are connected forming star point, and the three start terminals are connected to three copper slip rings fixed on the shaft. The mild steel shaft is passed through the centre of the rotor and fixed to the key.

The purpose of the shaft is to send mechanical power. Definition of Squirrel Cage Motor The motor which employing squirrel cage type rotor is known as the squirrel cage motor. The construction of the rotor is rugged and simple. The rotor of the motor consists the cylindrical laminated core having semi-closed circular slots and short circuit at each end by copper or aluminium ring, called short circuiting ring. It is not possible to add any external resistance in the rotor of the circuit. The rotor slots are not parallel but are skewed.

The skewing of the rotor has the following advantages. • Its reduces humming and thus ensuring the quiet running of a motor. • The skewed rotor gives smooth torque curves for different positions of the rotor.